Efficient intralogistics is one of the cornerstones of modern production. That’s why assembly lines have been considered a symbol of industrial progress since their invention. New devel-opments, such as frictionally-locking systems with roller drives and TPU coating, also offer advantages that go far beyond simply linking individual processes.

Precision transport

Belts transport millions of food products from the warehouse through production to the pack-aging plant, the cold storage facility or the loading station. Synchronous movements and pre-cise positioning play an increasingly important role given the high cycle rates of today’s pick-and-place systems. It’s always a matter of providing the required goods at the right place and in the desired quantity at a specific time, while guaranteeing the highest quality. In order to perform this task with precision, conveyor and processing belts must ensure smooth operation around the clock.

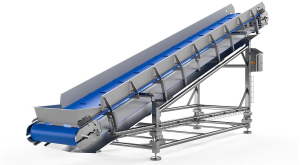

Karl Schnell, a supplier of process machines and internal transport systems, is active in this sensitive area of food technology. The supplier uses only frictionally-locking belts with roller drives for its conveyors. The advantage here is a stable tensile member made of polyester and aramid, which ensures a long service life and high dimensional stability even with heavy loads. Even gradients of up to 45 degrees are feasible in the systems.

When hygiene is required

The use of conveyor belts with a TPU-coated monolithic belt is recommended for conveying processes with the most demanding requirements for cleanliness and hygiene. Thermoplastic polyurethane (TPU) is often used in food processing as a belt coating material. The material is easy to use at very low temperatures, has excellent abrasion resistance and is resistant to vegetable and animal fats and oils. It is also advantageous during cleaning, as the belts have a smooth surface without porous spots and an even belt thickness. To prevent the growth of harmful microorganisms on the belt surface, Karl Schnell belts are also provided with antimi-crobial additives.

Optimisation of in-plant logistics processes

Whether belts with weighing systems for raw material standardisation or transport via metal detectors: If further options are required, the designers at Karl Schnell adapt the conveyor lines individually to the user’s requirements. Conveying capacities of up to 50 tons per hour can be realised.

Additional information and contact : KARL SCHNELL GmbH & Co. KG Winterbach, Germany Bernd Mehlau Marketing Manager Tel.: +49-(0)7181-962-115 E-mail: mareting@karlschnell.de Web: www.karlschnell.de