The Berchtesgadener Land dairy has invested in a new returnable-glass line for milk and cream and chosen Krones to supply vital parts of it.

Fresh milk produced using traditional methods is the cream of the crop. The Berchtesgadener Land dairy fills this precious commodity in glass bottles. To meet the soaring demand for milk in returnable bottles, the cooperative has replaced its returnable-glass line, which fills organic and mountain farmers’ milk and cream.

‘The cows are our key staff,’ say the folks at the Berchtesgadener Land dairy. And you immediately notice that they mean it. A life-size plush cow stands in the reception lobby of the modern, welcoming administration building, and in the seating area you feel a bit as if you were sitting on a mountain pasture. Large photos on screens in the canteen showcase cows in artful settings, and in the meeting room cow bells are used as lamp shades.

Everything here revolves around the cows, or to be more precise their milk, which is supplied by the approximately 1,800 farmers who own the cooperative. When you talk to the people working for the dairy, you cannot help but notice the deep sense of attachment they feel to “their” farmers and the top-quality milk they supply. The cooperative’s paramount business target is clearly perceptible: to preserve the existence of their farms, by fetching the best-possible milk price with high-grade products and smart marketing. The key priority is to preserve the smallholdings in the mountainous area between Watzmann and Zugspitze, in particular, where the average farm has 27 cows. They’d do almost anything here for their mountain farmers, even if that means driving a milk collection truck along winding mountain tracks to pastures located at elevations above 1,000 metres. They do that every other day in the summer season when the cows are up there.

Soaring demand for milk in returnable bottles

The Berchtesgadener Land dairy cooperative was founded in 1927, almost 100 years ago. Today, it has a payroll of 500 and processes 1.1 million litres of milk per day, turning them into more than 150 different products, ranging from a number of yoghurt and fromage-frais variants and cream right through to UHT, ESL and fresh milk. The dairy makes all those articles in-house at its Piding facility, most of them in conventional and organic quality. The cooperative was the first dairy in Germany to launch organic products in 1973, at that time working with five Demeter farms. The number of the cooperative’s organic farms has since grown to around 600, of which 100 belong to Demeter, Germany’s oldest organic farming association, and 500 to Naturland – Registered Association for Organic Agriculture.

“Traditional fresh milk is the most difficult product to make in our field,” says Paul Althammer, deputy production manager at the dairy. “We want to preserve everything we can in the milk and treat it to maximised standards of gentleness. This premium-quality product must be filled in premium-quality packaging, the glass bottle.” The dairy has filled its fresh milk into returnable glass containers since 1990. Soaring demand for milk in returnables caused some bottlenecks in the previous line, which was rated at 6,000 containers per hour. The situation even got so critical that the dairy had to temporarily cease production of the bottled conventional cream. In 2019, the cooperative decided to change its plans and to use a building that had originally been erected to accommodate filling lines for beverages cartons for a new returnable-glass line. This enabled the dairy to promise its customers that the popular bottled cream would return. The half-litre bottles with the green label then reappeared in the refrigerated display cases just in time for the 2022 strawberry season.

Altogether, the Berchtesgadener Land dairy has invested a sum in the two-digit millions into new buildings and the new line. For the cooperative’s farmers, that means having to do without the maximum possible milk money today, in favour of safeguarding their future. The expectations for the lines and systems are correspondingly high, as is the responsibility shouldered by project manager Paul Althammer.

The right stuff: traditional fresh milk in returnable bottles

The most important requirement for the new line was quality, both in regard to the machines and systems and the products made on them. “Production lines for traditional fresh milk must always give reliable service. We don’t have time for long maintenance routines,” emphasises Althammer. The milk is delivered to the dairy every day and must be dispatched fast, in order to guarantee retailers a minimum shelf life in the cold chain of eight days. What’s more, complying with stringent cleanliness standards in production is the top priority for filling this unsterilised milk. Germs carried in from outside result in faster milk spoilage, meaning the required shelf life would then not be met. When filling into returnable bottles, moreover, contaminated empties must not be allowed to enter the filling zone. That entails stringent requirements for the bottle washer, the filler and overall hygiene standards for the line.

Deputy production manager Paul Althammer started working for the Berchtesgadener Land dairy 28 years ago as a trainee: “All my working life here has been closely interwoven with milk bottles, so it was quite obvious who would be heading the returnable-glass-line project.”

We’re enjoying almost exotic niche status with our fresh milk produced using strictly traditional methods and filled in returnable bottles. Not many dairies offer that anymore. Paul AlthammerDeputy production manager

What exactly does “produced using traditional methods” mean?

Dairies mark real fresh milk with a shelf life of at least eight days “Produced using traditional methods”, thus distinguishing their exceptionally high-quality product from milk variants with a longer shelf life. The milk is pasteurised by heating it up as gently as possible at 72 to 75 degrees Celsius for 15 to 30 seconds. That ensures all pathogenic germs are reliably killed off but vitamins and the milk’s natural taste are preserved.

Maximised standards of hygiene for production reliability

The Berchtesgadener Land dairy has chosen Krones for key components of its line – bottle washer, rinser/filler block, labeller and the latter’s inspection systems. The two companies have known and appreciated each other since the first bottling line was purchased more than 30 years ago. “We feel we’re in good hands with Krones because their people really know what they’re doing. There are specialist experts for each line and system who can answer every question we have,” says Paul Althammer, adding: “The really good collaboration with the project team was yet another bonus. We also appreciate the geographical proximity because it means the same people mostly stay on the project until the line has been acceptance-tested.”

The new line fills fresh milk produced using traditional methods and is rated at 12,000 containers per hour. To be more specific: It fills Demeter milk into brown one-litre glass bottles and conventional milk from mountain farmers in transparent one-litre bottles (in the low-fat and full-fat variants), and organic Naturland and conventional cream in half-litre bottles at a speed of 15,000 containers per hour. The new building was completed in 2021 despite the coronavirus pandemic, so the line could be put into operation in early February 2022 as scheduled.

We feel we’re in good hands with Krones because their people really know what they’re doing. There are specialist experts for each line and system who can answer every question we have. Paul AlthammerDeputy production manager

The new returnable-glass line has achieved four goals:

• Quality improvement: The hygiene concept for the entire line has been designed to ensure significantly longer shelf-lives than retailers stipulate for traditional fresh milk. That provides reliability of production while also positioning the dairy to meet any future changes in consumers’ wishes.

• Cleanroom concept: Three zones were created in ascending stages of cleanliness. The first one is referred to as the “dirty area”. There the returned empties are fed into the bottle washer. This area has been completely partitioned off from the clean area, which starts at the bottle washer’s discharge end with clean bottles. A cleanroom atmosphere is created in the rinser/filler block, in order to further upgrade hygiene conditions during filling proper. You will find the exact details on that below.

• Less water: Thanks to the new bottle washer, fresh water consumption has been halved. Read more on this on the following page.

• Better working conditions: Last but not least, the fourth goal was to upgrade noise protection, in order to create a more pleasant and above all quieter working environment for the staff.

New technology – the details

Bottle washer dimensioned for long treatment times

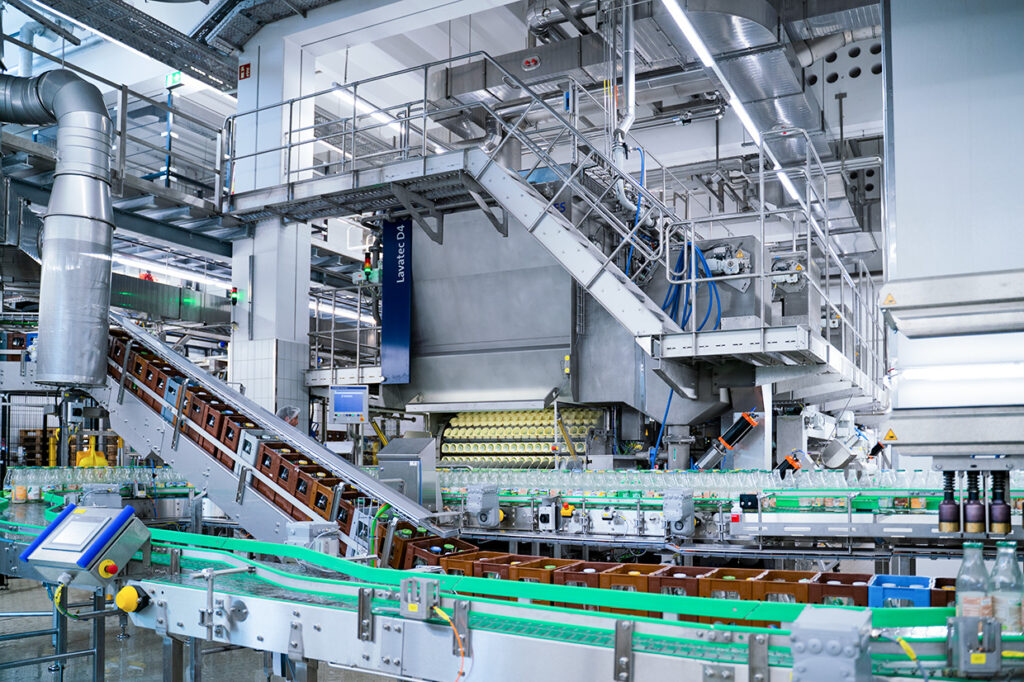

If production is to be divided into a dirty area and a clean area, a double-end bottle washer must be used, in order to provide a spatial separation between bottle infeed and bottle discharge. The new hall is divided into two sections by a ceiling-high wall running over the hall’s entire width. The bottle washer goes through an aperture in this wall sealed off by a stainless-steel frame. That neatly separates the bottle washer’s clean end from the rest of the hall. The Lavatec itself has been specifically designed to comply with the highest hygiene standards and is completely made of stainless steel, including important components. “We are manufacturers of premium products, so stainless-steel surfaces are first choice for our filling lines. That was very important to us. After all, we want to keep the line in good and presentable condition for a long time to come,” explains Paul Althammer. “Krones was able to satisfy this wish. What’s more, it was their overall concept that won us over.” The Lavatec D4 has a fair bit of work to do, in order to remove all the many fat and milk residues from the bottles that enter the machine. So the containers’ dwell time in the caustic section must be correspondingly long. To guarantee these long treatment times, the washer is particularly large. The bottle pre-treatment zone has been designed to prevent severe foaming, despite the lactoproteins’ marked propensity to foam. Hygienic design principles have been rigorously observed throughout the entire line: There are no corners or edges where residues might collect, and the discharge profiles guiding the clean bottles onto the conveyor belt are made of biocidal plastic, thus avoiding any recontamination. The Lavatec works with two caustic baths. The first one rinses off most of the soiling, and therefore the second caustic bath is hardly soiled at all. This two-chamber system substantially reduces the dirt load in the wastewater tank. Overall, the new bottle washer consumes half the amount of fresh water previously needed and significantly less chemicals.

Rinser/filler block: maximised standards of hygiene

The rinser/filler block has been designed to ensure that retailers reliably get a shelf life of eight days for fresh milk produced using traditional methods and to also provide an option for achieving longer shelf lives. “Krones was actually the only company that could offer the machine technology able to meet this stipulation,” says Althammer. “What’s more, we’d gained very good experience with our old Krones filler block.” The block consists of a Modulfill NWJ filler and an electronic twin-channel Moduljet rinser and meets the highest of hygienic requirements. A cleanroom roof fitted with HEPA air filters generates a cleanroom atmosphere during filling. In addition, a partition wall between filler and rinser prevents possible contamination caused by splashing from the rinser. The hygiene concept also includes a comprehensive automatic intermediate foam-cleaning function. The Modulfill has been equipped with non-contact filling valves for milk processing that also meet the hygiene standards for aseptic lines. Despite the difference in weight between the one-litre bottle and the 0.5-litre bottle and in the specific weight of cream and milk, weighing cells ensure accurate fill quantities for both products.

The rinser/filler block was quality-acceptance-tested by the dairy together with Krones’ validation team. Elaborate tests served to verify the stipulated best-before period and the suitability for ESL milk. To this end, UHT milk was monitored for sterility, filled and then checked. “Today, the line provides everything we’d hoped for,” says a satisfied Paul Althammer.

Filling low-fat and full-fat milk and even cream with 32 per cent fat content on one and the same filler was a genuine challenge. Low-fat milk causes severe foaming and has to flow in slowly at first. Cream, by contrast, must not be allowed to turn into butter and must therefore flow out slowly through a maximally large gap. The Modulfill, with its 45 valves, has a larger diameter than actually required for this output, in order to ensure a somewhat longer filling time for low-fat milk. The concept is working, says Althammer: “Milk is a natural product, its ingredients are not always the same and change, especially when the cows’ diet changes in spring and in autumn. Therefore, we had to reset new speeds every day for the low-fat milk in the old line. When low-fat milk was handled on the new filler for the first time, all of us could hardly wait to see how it would cope – and we were thrilled: There weren’t any problems at all. A perfect performance. Today, we simply set 12,000 bottles per hour, and the machine does the rest.”

Krones was actually the only company able to offer a rinser/filler block in the quality we need for fresh milk. Paul AlthammerDeputy production manager

Another vital requirement was fast product change-overs. The line fills six different fresh-milk products and is changed over several times every day. The Demeter milk, in particular, must not contain any traces of other products. “Change-over processes have to be perfect, with minimised wastage. After all, we’re dealing with a valuable raw material here,” says Althammer. Milk is used for rinsing to avoid any unnecessary standstills. But the “rinsing milk” is not wasted since it is drained into a special collecting trough installed in the filler, so that it can be processed to make other products.

Labeller: perfect dress for a top-quality product

The Ergomatic labeller, including a Checkmat EM inspector and an inkjet date printer, is the line’s third component supplied by Krones. This machine applies the striking green and blue labels of the Berchtesgadener Land dairy to the bottles. “It is important to us to present our precious Demeter and mountain farmers’ milk in perfect dress. With individual bottles standing in the refrigerated display cases, the first thing that catches the customers’ eye is the label and the bottle. So that has to be spot-on,” emphasises Althammer. “We started working with a Krones labeller in 1990 and bought our second one six years ago. So our mechanics and line operators are familiar with the machines, another vital aspect,” is how he explains why the dairy opted for Krones.

The challenge involved here is the tamper-evident label, which reaches from the bottle’s cap down onto the bottle. It must be glued to the cap and then folded straight down onto the bottle at a high speed. Cold glue is used here, although its adhesive power on the cap is lower. That’s because flaming the bottle cap was not an option as it could adversely affect the milk. “When the cap is flamed, the bottle’s head space is heated up but we don’t want to subject our product to that,” explains Althammer. “It was a joint effort but we managed it all right,” he adds, satisfied. The flat thin labels are glued onto the bottles with the same glue and brushed on. After that, the inkjet system prints the best-before date on them. The integrated Checkmat is the final station in the line where every bottle is inspected one by one before being packed into the transport crate. The high-resolution cameras check all bottle types for correct label placement and for imprint of fat contents and best-before date.

Everyone who’s seen the new line so far was thrilled, saying it has turned out a real success. Paul AlthammerDeputy production manager

The final acceptance test for the new returnable-glass line took place in July. The old bottling line had been dismantled quite some time ago. The dairy soon felt safe to take this step, relying on the new line, and the space was urgently needed. That has given the Berchtesgadener Land dairy a bit of scope for fresh-milk handling, demanding as that is. Paul Althammer is satisfied: “We did not have much room to accommodate the new line but it has been fitted into the space available really well. Everyone who’s seen it so far was thrilled, saying it has turned out a real success.”